Food Structure Journal 1982-1993:

Foods under the microscope: 1. Dairy products

with direct access to full-text papers.

1982-1993

History of the "Food Structure" Journal

An American organization, Scanning Electron Microscopy, Inc. (SEM Inc.), added foods as another subject of annual meetings in 1979. The meetings were very successful as they gave a global scale forum to food microscopists to present their findings and to exchange ideas and experience. The presentations were published in the hard-cover SEM journals published by SEM Inc. In preparation for starting a new journal specialized in food structure, all presentations were compiled in 1981 by D. N. Holcomb and M. Kaláb in the form of a book entitled "Studies of Food Microstructure", In 2014, it is still available on the book market. In 1982, a new scientific journal, Food Microstructure, was established. It is interesting to note the affiliations of its co-founders: Sam H. Cohen (Science & Advanced Technology Laboratory, US Army Natick R&D, Natick, MA), Eugenia A. Davis (Department of Food Science & Nutrition, University of Minnesota, St. Paul, MN), David N. Holcomb (Kraft Inc., Glenview, IL), and Miloslav Kaláb (Food Research Institute, Agriculture Canada, Ottawa, ON, Canada). These scientists thus represented academic research (E. Davis), industrial research (D. Holcomb), and government research, both civilian (M. Kaláb) and military (S. Cohen).

SEM Inc. financially supported scientists in developing countries to make their presentations in person under the condition that the resulting manuscripts will be published in Food Microstructure. Scientists from countries around the world served as Editorial Board members and additional scientists were appointed as editors. In 1990, Food Microstructure was renamed Food Structure at the suggestion by I. Heertje (The Netherlands) and the frequency of publication was doubled to 4 issues per annum. Although the journal was printed all on glossy paper to ensure high quality of the micrographs reproduced, annual subscription was low compared to similar scientific journals. It was $50.00 in 1982 and $100.00 in 1993. The journal was discontinued in 1993 by a sudden personal decision of the publisher, Om Johari (Scanning Microscopy International, AMF O'Hare, IL). Food scientists were thus deprived of their journal and also their annual meetings.

During the short, 12-year existence, 386 papers were published and the Tables of Contents are still available at these sites: Δ, Δ, Δ, and Δ. By the kind of paper, there were 279 research papers and 76 reviews. By subject, there were 79 research papers on dairy subjects, 61 on meat research, 53 on cereals, 47 on food lipids and their emulsions, 32 papers on legumes research, and 83 papers on other subjects including fruits, vegetables, mushrooms and even bacteria, food packaging materials and feeds. The Food Microstructure and Food Structure journal issues may be found in the libraries of many university departments of food science in the USA and in a few libraries in foreign countries. The journal, although defunct for 20 years, is also available at some on-line bookstores. The international reputation is reflected by the number and nationalities of the scientists who served on the Editorial Board. They represented the following 18 countries: Australia, Bulgaria, Canada, Denmark, France, Germany, Hungary, India, Israel, Italy, Japan, New Zealand, Sweden, Switzerland, The Netherlands, UK, USA, and Yugoslavia.

|

|

Until the 20th century, dry foods such as cereals and other seeds, legumes, and stable food sources (potatoes, cabbage, carrots, squash) were stored for the period of their shortage in winter or at a time of poor crops. Many perishable foods (fruits, vegetables, even meats including fish) were preserved at home. Pickling, salting, smoking, drying, cooking, baking etc. were done on a small scale. During World War II, the need to transport easy-to-prepare foods over long distances to the armies led to industrial food preservation which rapidly expanded after the war. Nowadays, the food industry produces ready-to-eat meals. Food preservation has moved from the households to the industry.

To preserve large quantities of foods, there is a need to understand the effects which cooling, freezing, drying, extended storage, atmospheric oxygen etc. have on them. To maintain high quality of the foods manufactured, there is a need to understand the processes which change the food sources into the finished products, e.g., milk into cheese or butter, flour into bakery products, meat into sausages etc. Chemical composition and nutritional values are not the only parameters affected by the processes mentioned.

Mouthfeel makes us to decide whether we like a particular food. It is closely related to microstructure. Is it smooth, granular, or fibrous? Uniform or heterogeneous? Do we want to improve it or to imitate it using different ingredients? There were times when it was believed that wieners, originally based on meat, could easily be made from milk powder. Imitating meat with soy protein was possible only when a similar fibrous microstructure was made using sophisticated technology. Fat imitations to be used in low-fat cheeses, ice creams, and dressings were made from milk curd only when microparticulation was developed to break the curd into particles approximately 1 µm; in diameter. Human tongue perceives all such particles, irrespective of the material used, as "fat".

There is a variety of laboratory techniques to study food microstructure. Light (optical) microscopy has been used for a long time. Individual food components such as proteins, fats, polysaccharides may be stained to be easily distinguishable under an optical microscope. This is an advantage of optical microscopy but its resolution is limited to several micrometres. Electron microscopy offers a considerably better resolution but the microscopes are very expensive both to buy and to maintain. Yet, the information provided by electron microscopy has been essential to the food industry and this has led to a rapid expansion of industrial as well as academic food research in the second half of the past century.

|

The subject of this presentation is the microstructure of foods with emphasis on scientific papers published in the Food Microstructure - Food Structure 1982-93 journal. Thanks to D. J. McMahon at the Utah State University in Logan, UT, USA, under whose initiative the Food Microstructure and Food Structure journal has been digitized, the links in the "References" lead to PDF files of the individual papers. References to other papers are also listed in related cases. Access to the "full text" of many of them may be obtained through ResearchGate by searching for the individual authors. Food scientists who study other foods such as cereals, meat, legumes, fruits and vegetables etc. are invited to contribute their fields of interest in a similar manner as this one. The Editor

| |

Information about the microstructure of foods is also available in books, food science journals and on the Internet. References to papers published in Studies of Food Microstructure (SFMS), Food Microstructure (FM), and Food Structure (FS) are listed at the end of each subject paragraph below. Several years ago, H. D. Goff (University of Guelph, ON, Canada) has provided a wealth of information online and he still maintains the Tables of Contents. Micrographs in colours of milk and dairy products illustrate a paper entitled The Beauty of Milk at High Magnification (which will re-appear shortly on the Internet at a new URL) that has also been published on paper in Infocus Magazine (The Proceedings of the Royal Microscopical Society, Issue 10, pp. 42-61, June 10, 2008).

Milk and dairy products

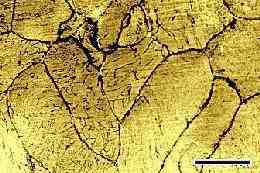

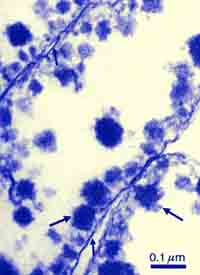

Milk consists of 3 major groups of components dispersed in a liquid phase (water) which participate in the formation of dairy products: proteins (casein and whey proteins), milkfat (milkfat globules, lipoproteins), and lactose (milk sugar). The latter participates in the development of cheese and cultured dairy products only after it is metabolized into lactic acid through bacterial action. Lactic acid acidifies the milk and coagulates the casein micelles. Coagulation of milk may also be achieved using other acids, e.g., hydrochloric. The micelles are too small (0.1 to 0.2 µm in diameter) to be seen by optical microscopy, yet they have their own submicroscopical structure. TEM using shadowing with platinum vapour (Fig. 1) shows them as globules. In milk, they are in constant motion and their free path is about 3 casein micelle diameters before they collide with another micelle (Fig. 2).

|

| Fig. 1. Casein micelles in cow's milk |

|

|

| Fig. 2. Casein micelles are always in motion. Large fat globules (upper right corner) are slowly ascending. |

| |

|

|

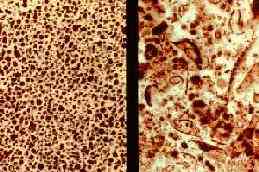

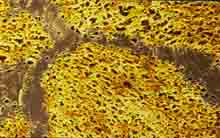

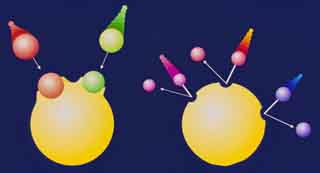

| Fig. 3. Casein micelles coagulate into clusters in milk which had not been heated and will produce cheese (left) but they coagulate into branched chains in milk that had previously been heated at >85°C for 10 min. and will produce yogurt (right). |

Following their destabilization by acidification and/or the presence of proteolytic enzymes such as chymosin, the casein micelles stop ricocheting and start sticking to each other. The milk curdles. The microstructure of the coagulum depends on whether the milk had been heated before coagulation. If not, the casein micelles produce large clusters (Fig. 3, left) which are easy to separate from the liquid phase called whey. The solid curd then forms the base for cheese production. There are very many cheese types.

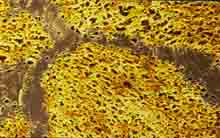

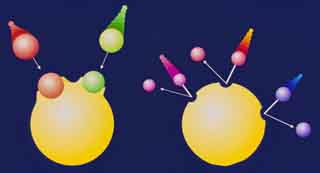

Yogurt and labneh

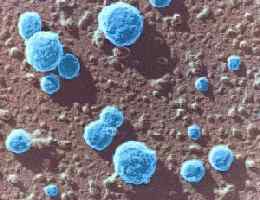

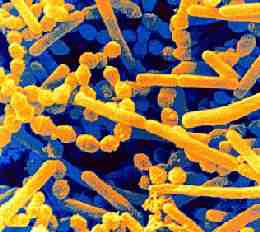

In milk, which had been heated above 85°C, the whey protein called β-lactoglobulin reacts with κ-casein on the surfaces of the micelles and blocks the sites where other casein micelles could get attached. The micelles still move freely in heated milk but the changes severely limit their interactions when the yogurt bacteria, Streptococcus thermophilus or Lactococcus lactis and Lactobacillus delbrueckii subsp. bulgaricus, (Fig. 4) acidify the milk with lactic acid. (Other "probiotic" lactic acid bacteria such as Lactobacillus acidophilus, lactococci, and also bifidobacteria may be used to make a varied microflora in yogurt). The micelles aggregate into short branched chains (Fig. 3, right). The liquid phase, i.e., the milk serum with all its nutrients including the whey proteins, is held by the "spongy" coagulum (Fig. 5). Whey proteins have high nutritional value because they provide sulfur in the form of amino acids cysteine and methionine. This is the principle of yogurt manufacture. "Strained yogurt" is called Labneh and its research was done do a great extent by A. Y. Tamime with collaborators.

References: - FM: Food Microstructure, FS: Food Structure.

1. The size distribution of casein micelles in camel milk. Z. Farah, M. W. Rüegg FM 8(2) 211-216, 1989.

2. Effect of heating to 200°C on casein micelles in milk: A metal shadowing and negative staining electron microscope study. V. R. Harwalkar, P. Allan-Wojtas, M. Kaláb FM 8(2) 217-224, 1989.

3. Structure formation in acid milk gels. I. Heertje, J. Visser, P. Smits FM 4(2) 267-278, 1985.

4. Development of microstructure in set-style nonfat yoghurt - a review. M. Kaláb, P. Allan-Wojtas, B. E. Phipps-Todd (Review paper) FM 2(1) 51-66, 1983.

5. Microstructure of set-style yoghurt manufactured from cow's milk fortified by various methods. A. Y. Tamime, M. Kaláb, G. Davies (Review paper) FM 3(1) 83-92, 1984.

6. A simple procedure for the preparation of stirred yoghurt for electron microscopy. P. Allan-Wojtas, M. Kaláb FM 3(2) 197-198, 1984.

7. Relationship between microstructure and susceptibility to syneresis in yoghurt made from reconstituted nonfat dry milk. V. R. Harwalkar, M. Kaláb FM 5(2) 287-294, 1986.

8. Electron dense granules in yoghurt: Characterization by X-ray microanalysis. E. M. Parnell-Clunies, Y. Kakuda, R. Humprey FM 5(2) 295-302, 1986.

9. Rheology and microstructure of strained yoghurt (labneh) made from cow's milk by three different methods. A. Y. Tamime, M. Kaláb, G. Davies FM 8(1) 125-136, 1989.

10. Changes in the rheology and microstructure of ropy yogurt during heating. J. A. Tegatz, H. A. Morris FS 9(2) 133-138, 1990.

11. Microstructure and firmness of labneh (high solids yoghurt) made from cow's, goat's and sheep's milks by a traditional method or by ultrafiltration. A. Y. Tamime, M. Kaláb, G. Davies, H. A. Mahdi FS 10(1) 37-44, 1991.

13. The effect of processing temperatures on the microstructure and firmness of labneh made from cow's milk by the traditional method or by ultrafiltration. A. Y. Tamime, M. Kaláb, G. Davies FS 10(4) 345-352, 1991.

14. Practical aspects of electron microscopy in dairy research. M. Kaláb (Tutorial paper) FS 12(1) 95-114, 1993.

|

|

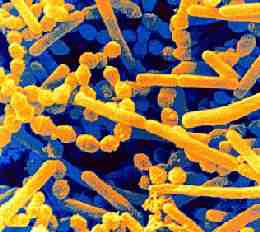

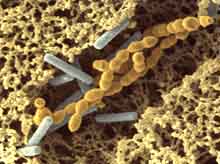

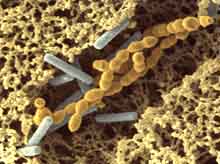

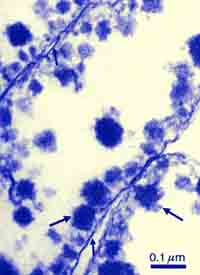

| Fig. 4. Yogurt bacterial culture consists of thermophilic streptococci (globules) and lactobacilli (rods) (SEM). |

|

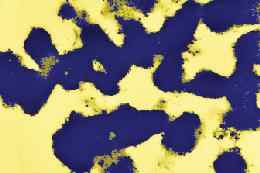

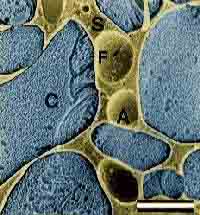

| Fig. 5. Branched casein micelle chains are characteristic of yogurt. S. thermophilus (yellow) and L. delbrueckii subsp. bulgaricus (blue) bacteria are also noticeable - SEM. |

The illustrations are micrographs obtained by scanning electron microscopy (SEM) and transmission electron microscopy (TEM). The micrographs are produced in grayscale because electrons instead of photons are used to form them. They were later provided with false colours using Adobe Photoshop.

TEM was done in two of several modes: Fig. 1 was obtained by capturing a very thin layer of casein micelles from diluted milk on a carbon-coated Formvar film on a 100-mesh grid, 3 mm in diamater, and shadowing the micelles under a sharp angle with platinum vapour in vacuo. The grid was examined in a beam of high-energy electrons and the shadows of the platinum coating were captured on a sensitive photographic film. That kind of film has been replaced in modern electron microscopes with digital cameras. Figs. 4 and 5 were obtained by SEM.

|

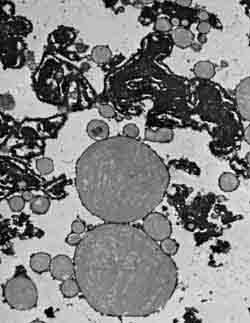

| Fig. 6. Cottage cheese (shown), cheese curd, and yogurt consist of compact casein micelles. (TEM of thin sections.)

|

|

| Fig. 7. Core-and-shell structure of casein micelles in Indian Paneer cheese. (TEM of thin sections.)

|

|

|

| Fig. 8. Queso blanco cheese. (Upper part: protein matrix displaying the core-and-shell structure; lower part: milkfat globules. - TEM).

|

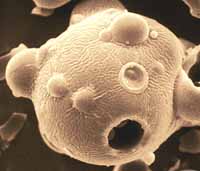

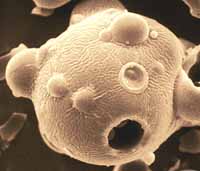

Bacteria were captured on a Nuclepore filters (pore size 0.4 µm, fixed with glutaraldehyde, dehydrated in alcohol, dried by critical-point drying, mounted on aluminum stubs, sputter-coated with gold, and examined.

Yogurt was trimmed into approx. 1.5×1.5 mm prisms 10-15 mm long. They were fixed and dehydrated in 100% ethanol and then rapidly frozen in liquid nitrogen. Ethanol unlike water does not form ice crystals and, thus, there were no artifacts from slow freezing. While in liquid nitrogen, the yogurt prisms were fractured, the fragments were thawed in 100% ethanol, critical-point dried, mounted on stubs, coated with gold and examined by SEM. Figs. 6 and 7 were obtained by TEM of thin sections. Particles, approx 1x1 mm, were fixed, dehydrated and embedded in a resin. Thin sections (90 nm) were cut using a diamond knife, stained for proteins with lead citrate and and captured on a carbon-coated Formvar film on a 100-mesh grid, 3 mm in diameter.

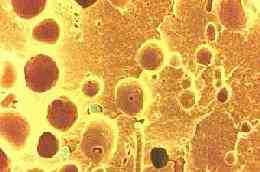

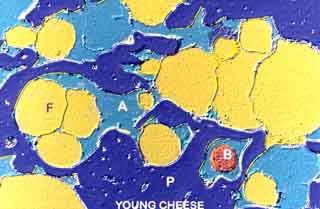

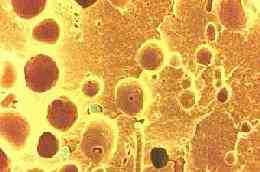

SEM shows branched casein micelle chains in yogurt (Fig. 5) and a compact protein mass of cheese (Fig. 10). Casein micelles which form both kinds of dairy products have similar internal structures as shown by TEM in Figs. 6 and 7. The core-and-shell structure in Indian cheese "Paneer" is the result of coagulating milk to a relatively high pH of 5.5 using an acid such as citric, tartaric, or hydrochloric. It is also found in other non-ripened cheeses such as the American White cheese and the South American Queso blanco. The structure may be observed only by TEM but not by SEM, because the annular space between the core and the shell is narrow (50-80 nm) and would be partly obscured by the usual 20 nm gold coating used in SEM as was shown by Kaláb in 1980 and confirmned by Gastaldi et al. in 1996. The structure is very stable and persists during cheese processing. Its presence in processed cheese thus indicates that non-ripened cheese was part of the ingredients.

References:

1. Milk gel structure. XII. Replication of freeze-fractured and dried specimens for electron microscopy. M. Kalab Milchwissenschaft 35(11) 657-662, 1980.

2. Development of microstructure in a cream cheese based on Queso blanco cheese. M. Kaláb, H. W. Modler FM 4(1) 89-98, 1985.

3. The role of beta-lactoglobulin in the development of the core-and-lining structure of casein particles in acid-heat-induced milk gels. V. R. Harwalkar, M. Kaláb FM 7(2) 173-180, 1988.

4. Development of microstructure in raw, fried, and fried and cooked Paneer made from buffalo, cow, and mixed milks. M. Kaláb, S. K. Gupta, H. K. Desai, G. R. Patil, FM 7(1) 83-92, 1988.

5. Structure, meltability, and firmness of process cheese containing White cheese. M. Kaláb, H. W. Modler, M. Caric, S. Milanovic, FS 10(3) 193-202, 1991.

6. Micellar transition state in casein between pH 5.5 and 5.0. E. Gastaldi, A. Lagaude, Tarodo de la Fuente, Journal of Food Science 61(1) 59-64 & 68, 1996.

|

Ripened cheese

|

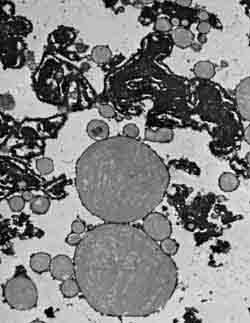

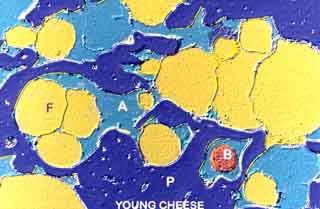

| Fig. 9. Young cheese: P (dark blue) - compact protein matrix; A (light blue) - aqueous phase, "whey"; F (yellow) - fat; B (red) - bacterium. (TEM).

|

|

| Fig. 10. Compression and ripening change coagulated casein micelles and the fat globules into compact cheese. (Fat removal from the sample produced globular cavities in the protein matrix - SEM).

|

|

Cheese is made from milk that had not been heated. Proteolytic enzymes such chymosin are used to coagulate the milk. They used to be obtained from calf stomachs as so-called rennet, but may also be of microbial or plant origin. A bacterial culture of specific lactic acid bacteria is used to provide characteristic flavour of the cheese. Structural changes taking place during the manufacture of various cheeses have been described and illustrated and also archived elsewhere.

|

|

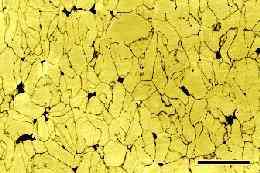

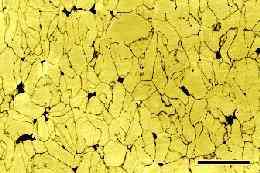

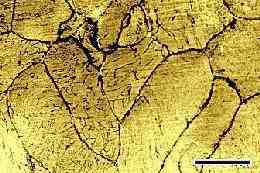

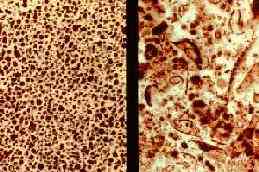

Fig. 11. Curd granule junction patterns. Top: Brick cheese patterns

Bottom: Cheddar cheese patterns. (Bar: 5 mm)

|

|

Curd granule and milled curd junction patterns

Hard cheeses are made by curdling milk in a large vat, cutting the curd into small cubes (6 - 16 mm) and slowly stirring the mass while heating it to expel whey from the curd cubes. Due to the loss of water, the cubes shrink into small curd granules. The whey is drained off and the curd settles at the bottom of the vat.

Cheddar cheese manufacture is similar but the curd in the vat is cut into large slabs and these are piled on top of each other at the vat wall. The warm slabs slowly flow down and the curd acquires a quasi fibrous structure. The slabs are reshuffled so all curd is exposed to this kind of "cheddaring". Then the curd is milled into finger-like particles. They are salted, placed into moulds, pressed, and ripened to form solid Cheddar cheese.

|

| Fig. 12. Curd granule junctions in Brick cheese are areas depleted of fat globules. Extraction of fat using n-hexane causes the cheese surface to reflect light and to appear lighter than the compact junctions.

|

To visualize the patterns, small cheese slices such as 30mm x 30mm x 2mm are fixed in 2.5% glutaraldehyde, dehydrated in graded ethanol, defatted in n-hexane and dried between 2 filter papers under a small load in a fume hood, the slices are sandpapered with a fine-grain sandpaper. The two different kinds of cheese produce two distinctly different types of patterns (Fig. 12). They are simple in the Brick cheese and complex in Cheddar cheese. The lines are areas where neighbouring curd granules are joined together. Cutting the curd leads to a loss of milkfat globules from the superficial layers of the granules. Subsequent pressing joins two fat-depleted layers and forms the so-called curd granule junctions. They appear darker to a naked eye. - In Cheddar cheese, the curd granules are elongated as the result of the cheddaring process. Thicker lines - milled curd granule junctions - are formed when the large finger-like particles fuse together. The origin of both kinds of patterns is explained with instructions how to obtain rhem. Large images of both kinds of junctions are shown on page 26 and in Fig. 16. Cheddar cheese commands a price higher than Brick cheese and some other stirred curd cheeses because of the more laborious manufacturing process which contributes to the quality of the cheese. Mechanized and automated cheddaring produces similar two kinds of junction

Internal structure of Swiss cheese loaves

|

| Fig. 13. Swiss (Emmental) cheese loaf by MRI. The dark structures in the loaf are cheese "eyes".

|

|

The image of an entire loaf of Swiss (Emmental) cheese at left (Fig. 13) showing its internal structure was obtained by M. Rosenberg et al. using magnetic resonance imaging (MRI). The objective was to assess the development of the "eyes" inside the cheese (dark areas inside the loaf) and to fully ripen only those with uniform eye distribution. This would allow the elimination of loaves with defective internal structure withut a need to cut the leaves. MRI is a non-destructive method which provides high-resolution images of air and whey pockets as small as 0.1×0.1×1 mm. The study saved space and energy for new loaves and made it possible to utilize the eliminated cheeses in other ways such as making processed cheese.

References:

1. Magnetic resonance imaging of cheese structure. M. Rosenberg, M. J. McCarthy, R. Kauten FS 10(3) 185-192, 1991.

2. Effects of protein concentration in ultrafiltration milk retentates and the type of protease used for coagulation on the microstructure of resulting gels. D. D. Gavarić, M. Carić, M. Kaláb FM 8(1) 53-66, 1989.

3. Composition and microstructure of soft brine cheese made from instant whole milk powder. M. M. Omar, W. Buchheim FM 2(1) 43-50, 1983.

4. A fluorescence microscopic study of cheese. S. H. Yiu FM 4(1) 99-106, 1985.

5. Properties of calcium caseinates with disparate performance in imitation cheese. K. Fleming, R. Jenness, H. A. Morris, R. Schmidt FM 4(2) 313-322, 1985.

6. Mechanical properties of cheese, cheese analogues and protein gels in relation to composition and microstructure. M. L. Green, K. R. Langley, R. J. Marshall, B. E. Brooker, A. Willis, J. F. V. Vincent FM 5(1) 169-180, 1986.

7. The crystallization of calcium phosphate at the surface of mould-ripened cheeses. B. E. Brooker FM 6(1) 25-24, 1987.

8. The size distribution and shape of curd granules in traditional Swiss hard and semi-hard cheeses. M. W. Rüegg, U. Moor FM 6(1) 35-46, 1987.

9. Amino acid composition and structure of cheese baked as a pizza ingredient in conventional and microwave ovens. A. Paquet, M. Kaláb FM 7(1) 93-104, 1988.

10. Changes in the microstructure of Saint Paulin cheese during manufacturre studied by scanning electron microscopy. M. Rousseau FM 7(1) 105-114, 1988.

11. Porosity, specific gravity and fat dispersion in Blue cheese. K. M. K. Kebary, H. A. Morris FM 7(2) 153-160, 1998.

12. Grittiness in a pasteurized cheese spread: A microscopic study. H. W. Modler, S. H. Yiu, U. K. Bollinger, M. Kaláb FM 8(2) 201-210, 1989.

13. Structure and rheology of string cheese. S. Taneya, T. Izutsu, T. Kimura, T. Shioya FS 11(1) 61-72, 1992.

14. Effect of draw pH on the development of curd structure during the manufacture of Mozzarella cheese. L. J. Kiley, P. S. Kindstedt, G. M. Hendricks, J. E. Levis, J. J. Yun, D. M. Barbano FS 11(3) 217-224, 1992.

|

Processed cheese

|

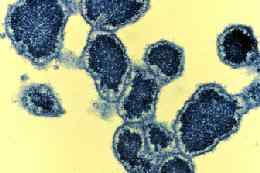

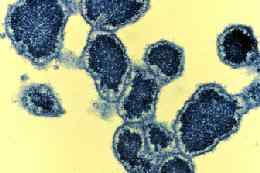

| Fig. 14. Processed cheese made with rework, i.e., cheese that had already been processed (small globular compact structures shown in blue). (TEM of thin sections.)

|

Cheese processing was initially invented to salvage trimmings from large cheese blocks or to salvage damaged cheese blocks. Fat separates from cheese on heating (as may be seen on a pizza) because heating impairs the emulsifying properties of cheese proteins. They may be restored by so-called melting salts such as sodium citrate or various sodium phosphates. Processed cheese of desired properties may be obtained from blends of selected natural cheeses with the addition of other ingredients (milk or vegetable protein solids) and appropriate melting salts. The resulting consistency of processed cheese may vary from spreadable to hard. The cheese may be produced in various shapes including slices and has become very popular.

Processed cheese is no more produced from scraps but is made nowadays from sources especially formulated for this purpose. If there is a problem somewhere in the line between processing and packaging and the flow of molten processed cheese has to be stopped, the cheese may harden in the pipes. Then it is necessary to recover it. In order to reduce losses, the hardened cheese is retrieved and milled and the resulting rework is added to a new batch of fresh cheese blend. TEM can detect rework in the form of "osmiophilic" areas in the new processed cheese (Fig. 14). Such areas, which appear dark in the micrographs, consist of proteins different from the fresh cheese blend, for example by being denser or by reacting more strongly with the osmium tetroxide fixative.

|

| Fig. 15. Foam bubble residues in milk. (Observations on the air-serum interface of milk foams. B. E. Brooker FM 4(2) 289-296, 1985.) (TEM).

|

References: - SFMS: Studies of Food Microstructure.

1. Microstructure and rheology of process cheese. A. A. Rayan, M. Kaláb, C. A. Ernstrom SFMS pp. 143-152, SEM/1980/III:635-643.

2. Effects of emulsifying agents on the microstructure and other characteristics of process cheese - A review. M. Carić, M. Gantar, M. Kaláb (Review paper) FM 4(2) 297-312, 1985.

3. Textural properties and microstructure of process cheese food rework. M. Kaláb, J. Yun, S. H. Yiu FM 6(2) 181-192, 1987.

4. Microstructure and firmness of processed cheese manufactured from Cheddar cheese and skim milk powder cheese base. A. Y. Tamime, M. Kaláb, G. Davies, M. F. Younis FS 9(1) 23-38, 1990.

5. Structure, meltability, and firmness of process cheese containing White cheese. M. Kaláb, H. W. Modler, M. Carić, S. Milanović FS 10(3) 193-202, 1991.

6. Processed cheese products. M. Carić, M. Kaláb. Chapter 15 In: Cheese, Chemistry, Physics and Microbiology, Vol. 2 Major Cheese Groups. P. F. Fox (editor) Chapman & Hall, pp. 467-505, 1993.

7. Practical aspects of electron microcopy in cheese research. M. Kaláb In: Chemistry of Structure-Function Relationship in Cheese. E. L. Malin, M. H. Tunick (editors), Plenum Press, New York, pp. , 1995.

|

Mysterious structures

Unknown structures consisting of thin protein sheets with minute globules attached to them (Fig. 15) were occasionally observed by TEM in milk. B. E. Brooker has found that they were the residues of milk foam which had developed during milking. Milk proteins become attached to the air-milk serum interface and form a membrane approx. 5 nm thick. Casein micelles then become attached to these membranes.

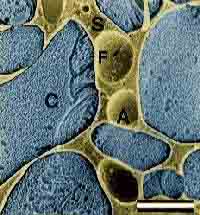

Ice cream

|

| Fig. 16. Ice cream by cryo-SEM. Author: H. D. Goff. The cross section shows 4 microscopic phases of frozen ice cream: ice crystals (blue - C), air bubbles (A), fat droplets (F) and the unfrozen phase (S - yellow).

|

Ice cream manufacture has been described in great detail on the University of Guelph, Ontario, website. H. D. Goff studied the ice cream structure by electron microscopy, using both cryo-SEM and TEM of thin sections after freeze substitution. Ice cream is both an emulsion and a foam. Physical chemistry of ice cream is quite complicated as there is a need to stabilize the minute air cells (bubbles) with partially coalesced milkfat. However, there is also advice for almost every problem which may develop during ice cream manufacture and storage.

In her article about ice cream, Bethany Halford has compiled information about the manufacture and properties from two university professors, H. D. Goff (Guelph, ON, Canada) and R. W. Hartel (Madison, WI, USA). In the USA, according to federal laws, anything that is labelled as "ice cream" must contain a minimum of 10% milkfat by weight. Premium brands may contain twice as much milkfat.

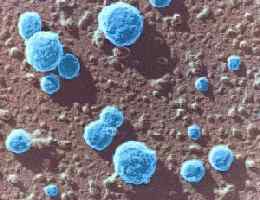

Meat binders

|

| Fig. 17. Fat globule membrane fragments (right) found in the sample are a proof of the presence of traditional buttermilk solids. Skimmilk contains only casein micelles (left). (TEM of thin sections.)

|

|

Milk solids are used in so-called meat binders to improve the cohesion of ingredients in meat batters. One kind of milk solids, those of dried traditional buttermilk, have been banned for a simple reason: lipids present in the buttermilk may be susceptible to becoming rancid on storage. Electron microscopy was found invaluable in the enforcement of the ban. The principle of the detection of buttermilk in the presence of other milk solids is based of the disruption of milkfat globules when cream is churned to produce butter. Fragments of the milkfat globule membranes are concentrated in buttermilk. A coarse suspension of a suspicious material is first centrifuged at low gravitional force and the supernatant is ultracentrifuged. The pellet is examined by TEM. A micrograph of milk solids free of buttermilk is shown in Fig. 17 (left frame). Membrane fragments in the right frame indicate the presence of buttermilk solids.

Milk powders

|

| Fig. 19. Milk powder. Interactions between large and still soft particles and small already dried and hard powder particles during spray drying lead to different surface structures on the large particles. If the large particles are very soft, they capture the smaller particles (image at left). If they are almost dry but still soft, the small particles ricochet and leave dents in the large particles (image at right).

|

Drying is the best method to store surplus milk. There were several drying procedures used in the past, the easiest having been roller drying. The milk powder produced was of limited solubility, however, so that it was not suited to make reconstituted milk (and make yogurt). Instead, it was used as an ingredient in some bakery products. Roller dry-ing was abandoned in favour of spray-drying.

|

| Fig. 18. Large milk powder particle with several smaller particles embedded in its surface.

|

The milk is first evaporated to remove a large part of the water. The evaporated milk is atomized into minute droplets in a drying tower. The size of the dried milk powder particles is related to the size of the droplets. The final appearance of the particles (Fig. 18) is the result of interactions taking place during drying. During drying, large and small particles collide. Large particles dry and harden more slowly than small particles (Fig. 19). Images of various milk powder particles may be viewed in Figs. 19-22. Instant milk powder, which dissolves easily without foaming, is made by agglomeration of the individual primary particles.

References:

1. Electron microscopic localization of solvent-extractable fat in agglomerated spray-dried whole milk powder particles. W. Buchheim FM 1(2) 233-238, 1982.

2. Particle structure in spray-dried whole milk and in instant skim milk powder as related to lactose crystallization. Z. Saito (Review paper) FM 4(2) 333-340, 1985.

3. Effect of lactose and protein on the microstructure of dried milk. V. V. Mistry, H. N. Hassan, D. J. Robison FS 11(1) 73-82, 1992.

4. Effects of drying techniques on milk powders quality and microstructure: A review. M. Carić, M. Kaláb FM 6(2) 171-180, 1987.

5. Lactose crystallization in spray-dried milk powders exposed to isobutanol. C. A. Aguilar, G. R. Ziegler FS 12(1) 43-50, 1993.

6. Effect of ionizing gamma-radiation on thermoluminescence and electron spin resonance intensities in milk protein concentrate powders. J. Kispéter, L. I. Horváth, L. I. Kiss FS 11(2) 165-170, 1992.

7. Concentrated and Dried Dairy Products. M. Carić, VCH Publishers (UK) Ltd., Cambridge, UK, 249 pp., 1994.

|

Additional references to other sources:

• Starch in Food: Structure, Function And Applications A. C. Eliasson (Ed.).

• Food Structure and Moisture Transfer V. Guillard, C. Bourlieu, N. Gontard. 2013, VII, 60 p. 13 illus., 6 illus. in color.

• Food structure: Creation and evaluation Edited by J. R. Mitchell and J. M. V. Blanshard, Woodhead Publ. Ltd., 1987,

400 pp.

• Food Microstructure Vol. 7-8, Scanning Electron Microscopy, Inc., Chicago, IL. 1988.

• Food Microstructure Publ.: Scanning Electron Microscopy, Inc., Chicago, IL. 1982-1989.

• Structure of Dairy Products (Google eBook) A. Y. Tamime, John Wiley & Sons, Apr 15, 2008, Techn. & Eng. - 304 pp.

• Chemistry of Structure-Function Relationships in Cheese E. L. Malin, M. H. Tunick (eds.),

• Microstructural Principles of Food Processing and Engineering J. M. Aguilera, D. W. Stanley. Springer, 1999 - Techn. & Eng.

432 pp.

• Image Analysis of Food Microstructure J. C. Russ. Taylor & Francis, 2005 - Science - 369 pp.

• Advances In Food Colloids E. Dickinson, D. J. McClements, Springer, 1996 - Techn. & Eng. - 333 pp.

• Food Microscopy O. Flint (Author), Olga Flint. RMS Microscopy Handbook 30, Bios Scientific Publ., Oxford, UK 1994.

• Immunohistochemical Detections Protocols for light microscopy examination of foods.

Updated: August 24, 2016.

©SCIMAT 2016

|